17. Property packages#

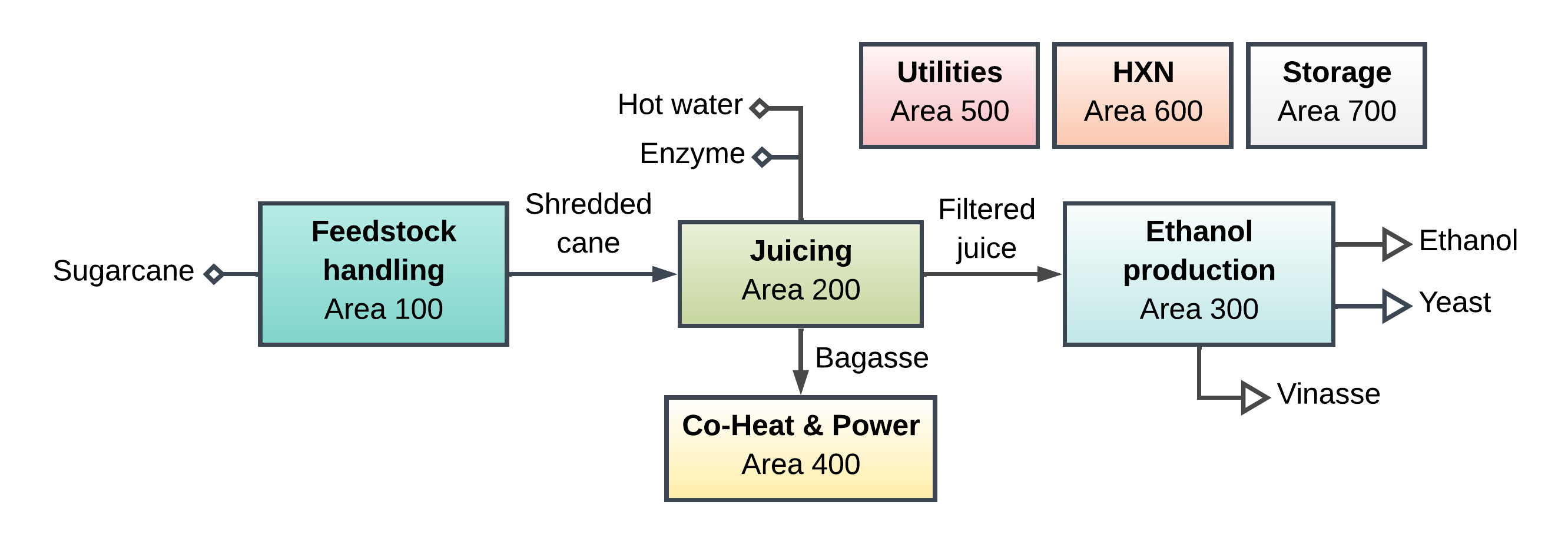

A Thermo object defines a thermodynamic property package. To build a Thermo object, we must first define all the chemicals involed. In the following example, we create a property package that BioSTEAM can use to model a sugarcane biorefinery producing ethanol from fermenting the juice and electricity from the burning the bagasse [1-2].

17.1. Creating chemicals#

Here is a demonstrative example of how to create chemicals from the databank and define new chemicals. The assumptions used here are reasonable but may not be accurate depending on the lignocellulosic feedstock:

[1]:

import thermosteam as tmo

from warnings import filterwarnings

filterwarnings('ignore')

chemicals = tmo.Chemicals(

['Water', # Define common chemicals by name

'Ethanol',

'Octane',

tmo.Chemical('Glucose', phase='s'), # These will always remain as solids

tmo.Chemical('Sucrose', phase='s'), # Specify phase if chemicals not in vapor-liquid equilibrium

tmo.Chemical('H3PO4', phase='s'),

tmo.Chemical('P4O10',

rho=1540, # Density [kg/m3]

default=True, # Default other chemicals properties like viscosity to that of water at 25 C

phase='s'),

tmo.Chemical('CO2', phase='g'), # Assume they will always remain a gas

tmo.Chemical('O2', phase='g'),

tmo.Chemical('Cellulose',

Cp=1.364, # Heat capacity [kJ/kg]

rho=1540, # Density [kg/m3]

default=True, # Default other chemicals properties like viscosity to that of water at 25 C

search_db=False, # Not in database, so do not search the database

phase='s',

formula="C6H10O5", # Glucose monomer minus water, molecular weight is computed based on formula

Hf=-975708.8), # Heat of formation [J/mol]

tmo.Chemical('Hemicellulose',

Cp=1.364,

rho=1540,

default=True,

search_db=False,

phase='s',

formula="C5H8O5", # Xylose monomer minus water

Hf=-761906.4),

tmo.Chemical('Lignin',

Cp=1.364,

rho=1540,

default=True,

search_db=False,

phase='s',

formula='C8H8O3', # Vainillin formula

Hf=-452909.632),

tmo.Chemical('Flocculant',

Cp=4.184,

rho=1540,

default=True,

search_db=False,

phase='s',

MW=1.), # No formula, so molecular weight should be defined

tmo.Chemical('Solids',

Cp=1.100,

rho=1540,

default=True,

search_db=False,

phase='s',

MW=1.),

tmo.Chemical('DryYeast',

rho=1540,

default=True,

search_db=False,

phase='s',

MW=1.,

aliases={'Yeast'}), # We can also give aliases to refer to them later

tmo.Chemical('CaO',

Cp=1.02388,

rho=1540,

default=True,

search_db=False,

phase='s',

formula='CaO'),

tmo.Chemical('Ash',

rho=1540,

Cp=0.37656,

default=True,

search_db=False,

phase='s',

MW=1.)]

)

# Compile once you are done adding chemicals so that the

# order of chemicals becomes immutable

chemicals.compile()

17.2. Mixture objects#

Before creating a Thermo property package, we must define the mixing rules to calculate mixture properties through a Mixture object:

[2]:

# Note that the mixture defaults to ideal mixing rules (weighted by mol)

# and excess energies are ignored by default

mixture = tmo.IdealMixture.from_chemicals(chemicals)

mixture.show()

IdealMixture(...

include_excess_energies=False

)

You can use the mixture for estimating mixture properties:

[3]:

array = chemicals.array

mol = array(['Water', 'Ethanol'], [2, 2])

H = mixture.H('l', mol, 300, 101325)

round(H)

[3]:

695

[4]:

mol = array(['Water', 'Ethanol'], [2, 2])

mixture.Cn('l', mol / mol.sum(), 300) # Normalize composition for result on a molar basis

[4]:

94.07098289709057

You can also estimate multi-phase mixture properties through methods that start with “x” (e.g. xCn):

[5]:

mol_liquid = array(['Water', 'Ethanol'], [2, 2])

mol_vapor = array(['Water', 'Ethanol'], [2, 2])

phase_data = [('l', mol_liquid), ('g', mol_vapor)]

Cn = mixture.xCn(phase_data, T=300) # Returns total capacity [J/K] because composition was not normalized

round(Cn)

[5]:

574

Note: To implement a your own Mixture object, you can request help through BioSTEAMDevelopmentGroup/thermosteam.

17.3. Thermo objects#

Once the chemicals and mixture objects are finalized, we can compile them into a Thermo object and set the default property package:

[6]:

tmo.settings.set_thermo(chemicals, mixture=mixture) # Set the default property package

tmo.settings.thermo.show()

Thermo(

chemicals=CompiledChemicals([Water, Ethanol, Octane, Glucose, Sucrose, H3PO4, P4O10, CO2, O2, Cellulose, Hemicellulose, Lignin, Flocculant, Solids, DryYeast, CaO, Ash]),

mixture=IdealMixture(...

include_excess_energies=False

),

Gamma=DortmundActivityCoefficients,

Phi=IdealFugacityCoefficients,

PCF=MockPoyintingCorrectionFactors

)

Note that a Thermo object contains ActivityCoefficients, FugacityCoefficients, and PoyintingCorrectionFactors subclasses to define fugacity estimation methods. By default, activities are estimated by Dortmund modified UNIFAC method, while vapor phase fugacity coefficients and Poyinting correction factors are assumed to be 1. If you plan on using all defaults, you can just use the chemicals to set the property package (and skip the creation of Thermo and Mixture objects):

[7]:

tmo.settings.set_thermo(chemicals)

tmo.settings.get_thermo()

Thermo(

chemicals=CompiledChemicals([Water, Ethanol, Octane, Glucose, Sucrose, H3PO4, P4O10, CO2, O2, Cellulose, Hemicellulose, Lignin, Flocculant, Solids, DryYeast, CaO, Ash]),

mixture=IdealMixture(...

include_excess_energies=False

),

Gamma=DortmundActivityCoefficients,

Phi=IdealFugacityCoefficients,

PCF=MockPoyintingCorrectionFactors

)

17.3.1. More rigorous thermodynamic calculations#

If you have mixtures with non-condensible gases, you may want to use IdealGasPoyintingCorrectionFactors to account for Poyinting effects:

[8]:

# Without Poyinting correction factors, the dew point is high

tmo.settings.set_thermo(['Butanol', 'CO2'], cache=True)

eq = tmo.equilibrium

s = tmo.Stream(None, Butanol=1, CO2=10, P=1e7)

s.dew_point_at_P()

[8]:

DewPointValues(T=470.72, P=10000000, IDs=('Butanol', 'CO2'), z=[0.091 0.909], x=[0.997 0.003])

[9]:

# With Poyinting correction factors, the dew point is lower

tmo.settings.set_thermo(['Butanol', 'CO2'], cache=True, PCF=eq.IdealGasPoyintingCorrectionFactors)

s = tmo.Stream(None, Butanol=1, CO2=10, P=1e7)

s.dew_point_at_P()

[9]:

DewPointValues(T=458.21, P=10000000, IDs=('Butanol', 'CO2'), z=[0.091 0.909], x=[0.995 0.005])

You may need more rigorous mixing rules and phase equilibrium for high-pressure processes. BioSTEAM features a wide selection of equations of state for estimating excess free energies and fugacity coefficients:

[10]:

chemicals = tmo.Chemicals(['H2', 'N2', 'CO2', 'H2O'])

tmo.settings.set_thermo(chemicals)

s_ideal_gas = tmo.Stream('ideal_gas', H2=10, N2=10, CO2=10, phase='g')

s_ideal_gas.vle(T=160, P=1e7)

print('H_ideal_gas:', round(s_ideal_gas.H))

s_ideal_gas.show('cwt')

mixture = tmo.SRKMixture.from_chemicals(chemicals) # Soave-Redlich-Kuang EOS

tmo.settings.set_thermo(chemicals, mixture=mixture, Phi=tmo.SRKFugacityCoefficients)

s_eos = tmo.Stream('eos', H2=10, N2=10, CO2=10, phase='g')

s_eos.vle(T=160, P=1e7)

print('H_eos:', round(s_eos.H))

s_eos.show('cwt')

H_ideal_gas: -306734

MultiStream: ideal_gas

phases: ('g', 'l'), T: 160 K, P: 1e+07 Pa

composition (%): (g) H2 8.55

N2 91

CO2 0.495

--- 236 kg/hr

(l) H2 2.39e-06

N2 13

CO2 87

--- 505 kg/hr

H_eos: -499936

MultiStream: eos

phases: ('g', 'l'), T: 160 K, P: 1e+07 Pa

composition (%): (g) H2 7.75

N2 90.3

CO2 1.94

--- 260 kg/hr

(l) H2 2.51e-06

N2 9.43

CO2 90.6

--- 480 kg/hr

17.3.2. References#

Huang, H., Long, S., & Singh, V. (2016) “Techno-economic analysis of biodiesel and ethanol co-production from lipid-producing sugarcane” Biofuels, Bioproducts and Biorefining, 10(3), 299–315. https://doi.org/10.1002/bbb.1640

Cortes-Peña, Y.; Kumar, D.; Singh, V.; Guest, J. S. BioSTEAM: A Fast and Flexible Platform for the Design, Simulation, and Techno-Economic Analysis of Biorefineries under Uncertainty. ACS Sustainable Chem. Eng. 2020. https://doi.org/10.1021/acssuschemeng.9b07040.

Hatakeyama, T., Nakamura, K., & Hatakeyama, H. (1982). Studies on heat capacity of cellulose and lignin by differential scanning calorimetry. Polymer, 23(12), 1801–1804. https://doi.org/10.1016/0032-3861(82)90125-2

Thybring, E. E. (2014). Explaining the heat capacity of wood constituents by molecular vibrations. Journal of Materials Science, 49(3), 1317–1327. https://doi.org/10.1007/s10853-013-7815-6