4. Unit operation results#

4.1. A note on design and modeling#

BioSTEAM includes a wide range of unit operation models and cost correlations adapted from design textbooks and literature [1-5]. Essential unit operations such as pumps, heat exchangers, flash vessels, mixer-settlers, and distillation columns are some of the most rigorously modeled and designed. Design requirements for these essential units are calculated based on design specifications such as operating temperature and pressure, feed conditions, construction material, and degree of separation. These design requirements include, but are not limited to, the heat-transfer area of heat exchangers, the size and thickness of pressure vessels, and number of stages in a distillation column. Other unit operation models are modeled as splitters (i.e., a specified fraction of each component entering a unit is separated), and the purchase price is estimated using size factor correlations that are ultimately a function of material flow rates. BioSTEAM chooses purchase price correlations and construction factors based on the design specifications and requirements for each unit operation. For detailed documentation and examples of each unit operation, visit the units subpackage documentation.

4.2. Distillation columns#

In the following example, BioSTEAM’s distillation column is used to highlight key details here on where do unit operations store results:

[1]:

from biosteam import Stream, settings

import biosteam as bst

bst.nbtutorial()

# First set the property package

settings.set_thermo(['Water', 'Ethanol'])

# Create the feed at the bubble point

feed = Stream('feed', Water=1.08e+03, Ethanol=586)

bp = feed.bubble_point_at_P()

feed.T = bp.T # Feed at bubble point temperature

# Create a distillation column and simulate

# Use BinaryDistillation for 2-components

# For 3+ components, use ShortcutColumn

# For rigorous distillation with side draws and feeds at multiple stages, use MESHDistillation

D1 = bst.BinaryDistillation(

'D1', ins=feed,

outs=('distillate', 'bottoms_product'),

LHK=('Ethanol', 'Water'), # Light and heavy keys

y_top=0.79, # Light key composition at the distillate

x_bot=0.001, # Light key composition at the bottoms product

k=1.25, # Ratio of actual reflux over minimum reflux

is_divided=True, # Whether the rectifying and stripping sections are divided

)

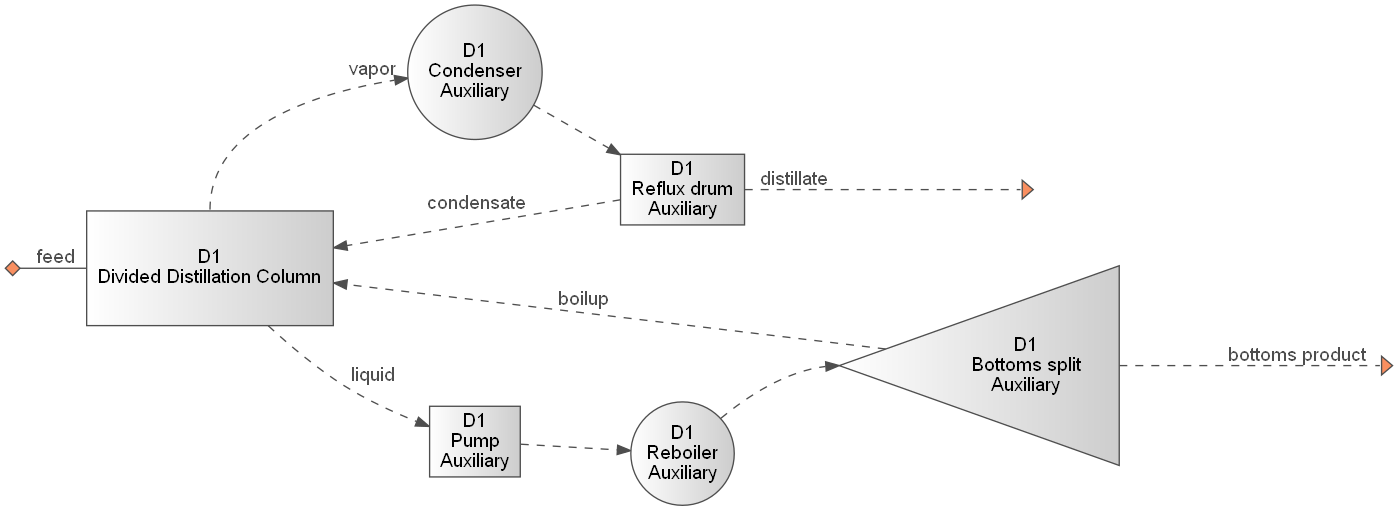

D1.diagram(format='png')

D1.show()

BinaryDistillation: D1

ins...

[0] feed

phase: 'l', T: 354.28 K, P: 101325 Pa

flow (kmol/hr): Water 1.08e+03

Ethanol 586

outs...

[0] distillate

phase: 'l', T: 298.15 K, P: 101325 Pa

flow: 0

[1] bottoms_product

phase: 'l', T: 298.15 K, P: 101325 Pa

flow: 0

Before simulating a distillation column, no results are available, streams are empty, and the components are initialized but empty as well:

[2]:

D1.design_results

[2]:

{}

[3]:

D1.purchase_costs

[3]:

{}

[4]:

D1.heat_utilities

[4]:

[]

[5]:

D1.power_utility

PowerUtility:

consumption: 0 kW

production: 0 kW

power: 0 kW

cost: 0 USD/hr

All unit operations have the design_results, purchase_costs, heat_utilities, and power_utility attributes. The heat_utilities attribute is a list of HeatUtility objects and the power_utility attribute is a PowerUtility object. Unit operations may also have attributes and components specific to that unit operation. Let’s look at the condenser within the diagram:

[6]:

D1.condenser.diagram()

D1.condenser.show()

HXutility: condenser

ins...

[0] vapor from BinaryDistillation-D1

phase: 'g', T: 298.15 K, P: 101325 Pa

flow: 0

outs...

[0] to RefluxDrum-reflux_drum

phases: ('g', 'l'), T: 298.15 K, P: 101325 Pa

flow: 0

After simulation, the unit operation along with its components will calculate all design results, purchase costs, and utilities:

[7]:

D1.simulate()

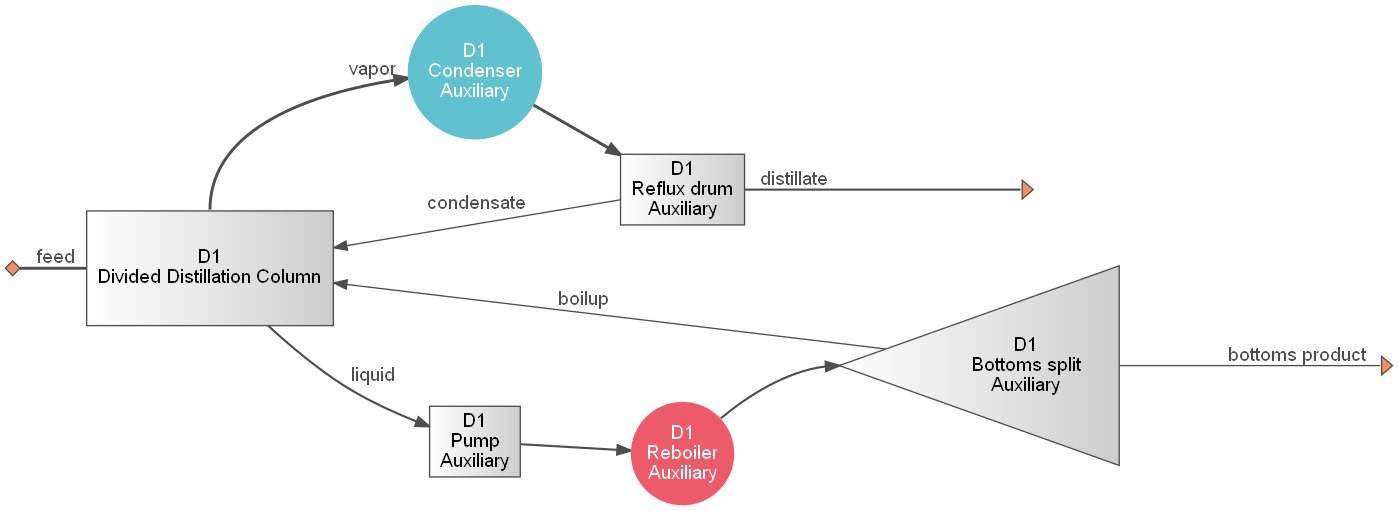

D1.diagram(format='png')

D1.show(T='degC', P='atm', composition=True)

BinaryDistillation: D1

ins...

[0] feed

phase: 'l', T: 81.125 degC, P: 1 atm

composition (%): Water 64.8

Ethanol 35.2

------- 1.67e+03 kmol/hr

outs...

[0] distillate

phase: 'g', T: 78.484 degC, P: 1 atm

composition (%): Water 21

Ethanol 79

------- 741 kmol/hr

[1] bottoms_product

phase: 'l', T: 99.64 degC, P: 1 atm

composition (%): Water 99.9

Ethanol 0.1

------- 925 kmol/hr

[8]:

D1.condenser.show()

HXutility: condenser

ins...

[0] vapor from BinaryDistillation-D1

phase: 'g', T: 351.72 K, P: 101325 Pa

flow (kmol/hr): Water 329

Ethanol 1.13e+03

outs...

[0] to RefluxDrum-reflux_drum

phases: ('g', 'l'), T: 351.63 K, P: 101325 Pa

flow (kmol/hr): (g) Water 156

Ethanol 585

(l) Water 173

Ethanol 540

[9]:

D1.design_results

[9]:

{'Theoretical feed stage': 26,

'Theoretical stages': 31,

'Minimum reflux': 0.7708367097030262,

'Reflux': 0.9635458871287828,

'Rectifier stages': 45.0,

'Stripper stages': 9.0,

'Rectifier height': 78.940416,

'Stripper height': 25.804416,

'Rectifier diameter': 9.960477527218737,

'Stripper diameter': 7.836628484724038,

'Rectifier wall thickness': 0.4375,

'Stripper wall thickness': 0.375,

'Rectifier weight': 41837.555210317725,

'Stripper weight': 12158.19021210372}

[10]:

D1.purchase_costs

[10]:

{'Rectifier trays': 90190.76854619542,

'Stripper trays': 19469.07052587847,

'Rectifier tower': 154203.6774309562,

'Stripper platform and ladders': 48571.69910583489,

'Stripper tower': 69659.22647677979,

'Rectifier platform and ladders': 17028.366373260913,

'Condenser - Floating head': 65778.41245145093,

'Reflux drum - Vertical pressure vessel': 40913.03779781813,

'Reflux drum - Platform and ladders': 10650.872732593733,

'Pump - Pump': 4526.2951512221225,

'Pump - Motor': 440.800042798914,

'Reboiler - Floating head': 65109.26213301633}

[11]:

D1.heat_utilities

[11]:

[<cooling_water: -2.84e+07 kJ/hr, 1.94e+04 kmol/hr, 9.45 USD/hr>,

<low_pressure_steam: 6.26e+07 kJ/hr, 1.62e+03 kmol/hr, 385 USD/hr>]

[12]:

D1.power_utility

PowerUtility:

consumption: 2.49 kW

production: 0 kW

power: 2.49 kW

cost: 0.195 USD/hr

The results() method can conviniently present all these results:

[13]:

D1.results()

[13]:

| Divided Distillation Column | Units | D1 | |

|---|---|---|---|

| Electricity | Power | kW | 2.49 |

| Cost | USD/hr | 0.195 | |

| Cooling water | Duty | kJ/hr | -2.84e+07 |

| Flow | kmol/hr | 1.94e+04 | |

| Cost | USD/hr | 9.45 | |

| Low pressure steam | Duty | kJ/hr | 6.26e+07 |

| Flow | kmol/hr | 1.62e+03 | |

| Cost | USD/hr | 385 | |

| Design | Theoretical feed stage | 26 | |

| Theoretical stages | 31 | ||

| Minimum reflux | Ratio | 0.771 | |

| Reflux | Ratio | 0.964 | |

| Rectifier stages | 45 | ||

| Stripper stages | 9 | ||

| Rectifier height | ft | 78.9 | |

| Stripper height | ft | 25.8 | |

| Rectifier diameter | ft | 9.96 | |

| Stripper diameter | ft | 7.84 | |

| Rectifier wall thickness | in | 0.438 | |

| Stripper wall thickness | in | 0.375 | |

| Rectifier weight | lb | 4.18e+04 | |

| Stripper weight | lb | 1.22e+04 | |

| Purchase cost | Rectifier trays | USD | 9.02e+04 |

| Stripper trays | USD | 1.95e+04 | |

| Rectifier tower | USD | 1.54e+05 | |

| Stripper platform and ladders | USD | 4.86e+04 | |

| Stripper tower | USD | 6.97e+04 | |

| Rectifier platform and ladders | USD | 1.7e+04 | |

| Condenser - Floating head | USD | 6.58e+04 | |

| Reflux drum - Vertical pressure vessel | USD | 4.09e+04 | |

| Reflux drum - Platform and ladders | USD | 1.07e+04 | |

| Pump - Pump | USD | 4.53e+03 | |

| Pump - Motor | USD | 441 | |

| Reboiler - Floating head | USD | 6.51e+04 | |

| Total purchase cost | USD | 5.87e+05 | |

| Utility cost | USD/hr | 395 |

Note that the units for the design results are in the _units dictionary:

[14]:

D1._units

[14]:

{'Minimum reflux': 'Ratio',

'Reflux': 'Ratio',

'Rectifier height': 'ft',

'Rectifier diameter': 'ft',

'Rectifier wall thickness': 'in',

'Rectifier weight': 'lb',

'Stripper height': 'ft',

'Stripper diameter': 'ft',

'Stripper wall thickness': 'in',

'Stripper weight': 'lb',

'Height': 'ft',

'Diameter': 'ft',

'Wall thickness': 'in',

'Weight': 'lb'}

It is also possible to retrieve design results in another set of units:

[15]:

rectifier_height = D1.get_design_result('Rectifier height', 'meter')

round(rectifier_height)

[15]:

24

For completeness, here are the rest of the results:

[16]:

D1.condenser.diagram()

D1.condenser.show()

HXutility: condenser

ins...

[0] vapor from BinaryDistillation-D1

phase: 'g', T: 351.72 K, P: 101325 Pa

flow (kmol/hr): Water 329

Ethanol 1.13e+03

outs...

[0] to RefluxDrum-reflux_drum

phases: ('g', 'l'), T: 351.63 K, P: 101325 Pa

flow (kmol/hr): (g) Water 156

Ethanol 585

(l) Water 173

Ethanol 540

[17]:

D1.reboiler.diagram()

D1.reboiler.show()

HXutility: reboiler

ins...

[0] from Pump-pump

phase: 'l', T: 370.63 K, P: 101325 Pa

flow (kmol/hr): Water 2.36e+03

Ethanol 19.6

outs...

[0] to PhaseSplitter-bottoms_split

phases: ('g', 'l'), T: 372.79 K, P: 101325 Pa

flow (kmol/hr): (g) Water 1.44e+03

Ethanol 18.7

(l) Water 924

Ethanol 0.925

Unit operations may also have special methods that you may find useful:

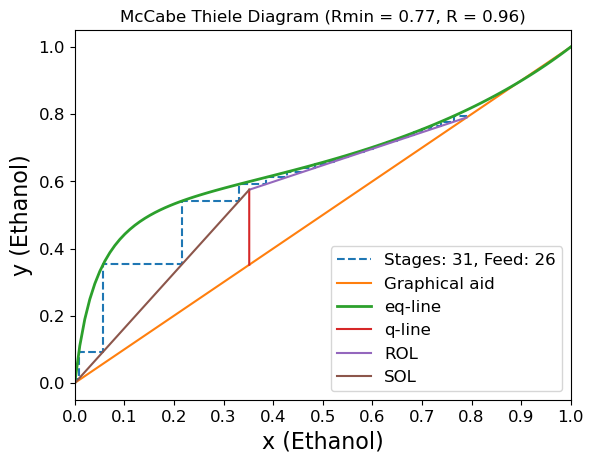

[18]:

from matplotlib import pyplot as plt

D1.plot_stages()

plt.show()

4.3. References#

Seider, W. D.; Lewin, D. R.; Seader, J. D.; Widagdo, S.; Gani, R.; Ng, M. K. Cost Accounting and Capital Cost Estimation. In Product and Process Design Principles; Wiley, 2017; pp 426−485.

Svrcek, W. Y.; Monnery, W. D. Design Two-Phase Separators Within the Right Limits. In Chemical Engineering Progress (CEP); The American Institute of Chemical Engineers, 1993; pp 53−60.

Apostolakou, A. A.; Kookos, I. K.; Marazioti, C.; Angelopoulos, K. C. Techno-Economic Analysis of a Biodiesel Production Process from Vegetable Oils. Fuel Process. Technol. 2009, 90, 1023−1031.

Green, D. W. Distillation. In Perry’s Chemical Engineers’ Handbook, 9 ed.; McGraw-Hill Education, 2018.

Duss, M.; Taylor, R. Predict Distillation Tray Efficiency. Chem. Eng. Prog. 2018, 24−30.